When planning an artificial grass project, you’ll likely come across various specifications in quotations and samples provided by suppliers. These specifications play a crucial role in determining the quality, lifespan, and cost of artificial grass. To make informed decisions, it’s essential to understand what these specifications mean. In this article, we will explain the key specifications in detail.

1. Pile Height:

Pile height refers to the height of the blade or fiber on top of the artificial grass backing. It is measured in millimeters (mm). Different pile heights offer varying aesthetics and performance characteristics.

2. Dtex:

Dtex is a unit of measurement that indicates the linear mass of yarn in grams per 10,000 meters. It represents the weight of the yarn used in the artificial grass. Higher Dtex values indicate higher face weight, which means more yarn is used, resulting in better durability and a denser feel. However, it’s important to note that exaggerated Dtex values may sometimes be provided by suppliers, so it’s advisable to verify them with professional equipment.

3. Gauge:

Gauge refers to the distance between two adjacent lines on the artificial grass. It is typically measured in inches. Common gauge options include 3/8 inch, 3/4 inch, 5/8 inch, 3/16 inch, and 5/32 inch. The gauge determines the density of grass in the width direction.

4. Stitch Rate:

Stitch rate refers to the number of stitches per 100cm in the stitch line direction. It represents the density of artificial grass. Higher stitch rates indicate a denser surface.

5. Density:

Density refers to the number of stitches in one square meter of artificial grass. It can be calculated using the gauge and stitch rate. By multiplying the number of lines in one meter (determined by the gauge) with the stitch rate, you can determine the density of the artificial grass.

5.1 Calculating Density with Gauge and Stitch Rate

To calculate the density of artificial grass using the gauge and stitch rate, follow these steps:

Step 1: Convert the gauge measurement to centimeters (cm). For example, if the gauge is given as 3/8 inch, convert it to centimeters by multiplying it by 2.54. In this case, 3/8 inch is approximately 0.9525 cm.

Step 2: Determine the number of lines in 100 cm based on the converted gauge measurement. Divide 100 cm by the gauge measurement in centimeters. For example, if the gauge is 0.9525 cm, divide 100 cm by 0.9525 cm to get approximately 105 lines in 100 cm.

Step 3: Multiply the number of lines by the stitch rate. This will give you the number of stitches in 100 cm. For example, if the stitch rate is 170 stitches/100 cm, multiply 105 lines by 170 stitches to get 17,850 stitches in 100 cm.

Step 4: Since density is measured in stitches per square meter (m²), the calculated number of stitches in 100 cm represents the density of the artificial grass. Therefore, in this example, the density would be 17,850 stitches/m².

By following these steps, you can accurately calculate the density of the artificial grass based on the given gauge and stitch rate specifications.

6. Backing:

Artificial grass backings consist of two components: the primary backing and the secondary backing. Each plays a crucial role in providing stability and durability to the overall system. Here’s a breakdown of these two backings:

6.1 Primary Backing:

The primary backing is made of woven polypropylene fabrics. Its main function is to provide a foundation for the artificial grass fibers to be tufted or stitched into rows. The primary backing also facilitates the seaming process between artificial grass panels, ensuring a secure and seamless installation. In most cases, the primary backing is comprised of a layer of polypropylene (PP) fabric.

6.2 Secondary Backing:

The secondary backing, sometimes referred to as the “coating,” is applied to the reverse side of the primary backing. Its purpose is to permanently lock the tufted fibers in place, enhancing dimensional stability and preventing the fibers from pulling out. Two common types of coatings used for the secondary backing are SBR Latex and Polyurethane (PU). SBR Latex is widely used in the market due to its good performance and cost-effectiveness. Polyurethane, while offering superior qualities, comes at a higher cost.

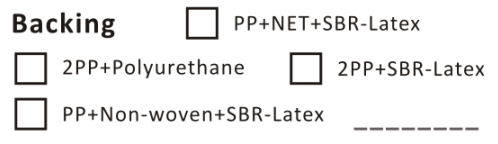

On our specification labels, we mark the backing as follows:

- PP+NET+SBR Latex: Polypropylene fabric + Net + SBR Latex Coating (commonly used)

- 2PP+Polyurethane: Two layers of Polypropylene fabric + PU coating

- 2PP+SBR Latex: Two layers of Polypropylene fabric + SBR Latex Coating

- PP+Nonwoven+SBR Latex: Polypropylene fabric + Non-woven fabric + SBR Latex Coating (same cost as PP+NET+SBR Latex)

Understanding these specifications will help you make informed decisions when selecting the right artificial grass for your project. Consider the specific requirements of your application and consult with professionals to ensure you choose the most suitable product.

Further Reading: Explore our Artificial Grass Glossary for a comprehensive reference on common terms used in the artificial grass industry.